Advanced Manufacturing Techniques: In-Mold Decorations Explained

Wiki Article

Mastering In-Mold Decorations: Methods, Trends, and Ideal Practices for Optimal Outcomes

In the realm of manufacturing, the art of in-mold decors stands as an essential facet of product layout and production. As markets continually seek cutting-edge ways to improve aesthetic appeal and functionality, grasping the intricacies of in-mold designs has actually arised as an important ability set. From choosing the appropriate materials to integrating sophisticated design patterns, the trip in the direction of achieving ideal outcomes in this domain name is multifaceted. By delving right into the approaches, trends, and best methods that underpin effective in-mold decor processes, companies can open a world of opportunities that not just elevate the aesthetic appeal of their items however additionally streamline production efficiency and reinforce customer involvement.Product Option

Material option is an essential element of mastering in-mold designs, as it directly affects the quality and longevity of the final item. When selecting products for in-mold decorations, it is crucial to think about factors such as compatibility with the molding process, the wanted aesthetic result, and the environmental problems the item will deal with.Moreover, the chosen product ought to have excellent bond residential properties to ensure that the design sticks firmly to the substrate throughout the molding procedure. Adhesion between the product and the decor is crucial for stopping delamination and making certain long-lasting visual charm. In addition, products with high heat resistance are chosen for in-mold designs, specifically for items that will be exposed to elevated temperatures throughout their lifecycle. By very carefully choosing the ideal product for in-mold decorations, producers can improve the general high quality and durability of their products, meeting the expectations of both clients and end-users.

Style Technology

An important consider advancing the area of in-mold decors is the continual expedition and application of style innovation techniques. Layout advancement plays a vital function in enhancing the aesthetic allure, capability, and general high quality of products made utilizing in-mold design processes. By including ingenious design components, makers can differentiate their items in the marketplace, draw in consumers, and remain ahead of rivals.One of the key facets of style innovation in in-mold decors is the combination of intricate patterns, appearances, and graphics that were formerly challenging to attain with standard decoration methods. Advanced modern technologies such as 3D printing and digital design tools allow developers to produce facility and in-depth designs that can be effortlessly transferred onto shaped parts. Furthermore, the use of lively shades, metallic coatings, and special impacts like gloss or matte textures can additionally elevate the aesthetic charm of in-mold embellished products.

Moreover, design advancement extends beyond visual appeals to incorporate functional enhancements such as ergonomic forms, incorporated features, and adjustable components that cater to particular customer demands. By embracing style technology, manufacturers can unlock brand-new opportunities for product, creativity, and personalization distinction in the competitive landscape of in-mold decors.

Manufacturing Efficiency

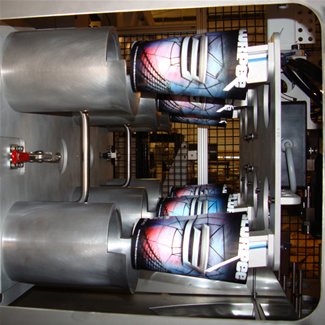

Efficient manufacturing procedures are necessary for equating the ingenious styles developed in the area of in-mold decors right into top notch completed products straight from the source that fulfill market demands and consumer assumptions. In the world of in-mold decorations, manufacturing effectiveness includes various vital elements that contribute to the total success of the production process.Automation not just increases the manufacturing procedure but also enhances precision and repeatability, leading to a much more uniform and top notch end item. Overall, a holistic method to production effectiveness is vital in making best use of the potential of in-mold decor strategies and attaining optimum outcomes in the affordable market landscape.

Quality Assurance Procedures

What are the essential strategies for making sure strict top quality control steps in the world of in-mold designs? Quality control actions are vital in in-mold decoration procedures to ensure the manufacturing of top quality and remarkable finished products.Making use of advanced modern technologies such as automated assessment systems can additionally improve the quality assurance process by giving accurate and trusted data for evaluation. These systems can spot flaws that might be missed by hands-on examinations, thereby enhancing general item quality and consistency.

Normal training and development programs for workers included in the in-mold decor process can also contribute to keeping top quality criteria. By enlightening staff on best methods, high quality assumptions, and the relevance of focus to detail, companies can foster a culture of high quality consciousness throughout the organization.

Customer Charm

To boost the bankability of in-mold decor items, providing and understanding to customer preferences play a crucial function in identifying their charm and success. Consumer charm in in-mold designs is influenced by different elements, consisting of layout looks, shade options, sturdiness, and general performance. Customers are increasingly seeking customized and special items that show their individuality and style. For that reason, providing customization alternatives such as personalized layouts, shade variations, and textural elements can significantly boost the charm of in-mold design products.

Verdict

In-mold decors supply a efficient and versatile means to improve product aesthetic appeals. Mastering in-mold decors calls for an alternative approach that considers all facets of the manufacturing process to visit their website make certain success.In the realm of manufacturing, the art of in-mold decors stands as an essential aspect of item style and production. Style development plays an essential duty in improving the aesthetic appeal, functionality, and general quality of items manufactured making use of in-mold design procedures.One of the essential aspects of style innovation in in-mold decors is the integration of detailed patterns, textures, and graphics that were formerly challenging to accomplish with traditional design get redirected here methods.Effective manufacturing processes are crucial for translating the cutting-edge designs established in the area of in-mold decorations right into top quality ended up items that meet market needs and customer expectations. Using customization choices such as tailored designs, color variants, and textural components can significantly improve the allure of in-mold decoration items.

Report this wiki page